|

Introduction

"The Mystery of Bronzes" is an exhibition that attempts to use modern high technology forms of multimedia facilities to portray the development of high technology in the Shang and Chou dynasties, which took the form of smelting metals and casting bronze objects. The virtual displays and fully digitized ways of presentation in this exhibit include a great deal of animation to recreate the complex processes that went into the high technology of ancient China, thereby offering audiences with an informative and entertaining understanding of the wisdom of the ancients.

Exploration and Discovery

How were bronze vessels made during the Shang and Chou dynasties? Many years of archaeological efforts and a series of investigative trials and experiments in casting have uncovered some of the steps by which they were produced. The process can be generally divided into two primary phases: "smelting" and "casting".

Smelting is the process of extracting a metal from its ore and then refining it to a higher purity. In the case of bronze, it is an alloy (mixture) of the metals copper, tin, and lead. Once this process is complete, the raw materials (metals) are transported to political centers and large settled communities with the requisite technology to undertake the process of casting.

Copper ingots excavated from an ancient smelting site

at T'ung-lü Mountain, Ta-yeh, Hupeh

|

|

| Stills from the animation for casting techniques |

This part of the exhibit offers a reconstruction of what raw materials may have looked like in the smelting process of the pre-Ch'in era, based on archaeological evidence derived from an ancient mine and smelting operations at T'ung-lü ("Bronze Green") Mountain, located in the district of Ta-yeh ("Great Refining"), Hupeh. At the same time, it presents a virtual representation of a possible casting process derived from the efforts of many researchers on early technology. Furthermore, the artifacts themselves reveal hints of the casting procedures used, but these are usually well hidden. Fortunately, with the advent of modern x-ray photography, vestiges of the original casting process can now be thoroughly revealed.

X-rays of various bronze objects

Information on Mining Areas

Natural Treasures Buried Below "Copper Grass"

Elsholtzia is a kind of special plant that grows well in soil with a high copper content. Since copper is an important element for its growth, the places where this grass-like plant thrives are almost always located not far from a rich natural source of copper ore. Hence, it was given the name "copper grass".

Copper Grass

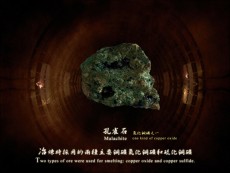

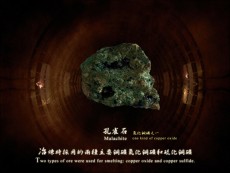

Ores Used for Smelting

Two types of ore were used for smelting copper: copper oxide and copper sulfide. Copper oxide was used relatively early in the history of copper smelting, because it is found in veins nearer to the surface, is marked by brighter colors that make it more distinguishable, and is easier to process.

Malachite

Never-ending Treasures of Ancient Mine Shafts

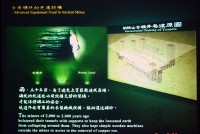

Modern geological surveys show that the majority of copper deposits in China are concentrated in four main areas. Located in the middle and lower reaches of the Yangtze River, Mt. Chung-t'iao, the Szechwan-Yunnan area, and Kansu Province, these account for two-thirds of the total amount of copper produced. During the surveys of these areas, geologists also have discovered evidence of ancient mine shafts in almost all the quarries.

Distribution map of ancient mining areas

Advanced Facilities in Ancient Mines

Though the mines are ancient, the safety of their facilities do not pale in comparison to those of today. Despite the vast expanses of time between then and now, ancient mining technology is still being used today!

|

|

| Mine and ore separation trough |

Born of Flames: The Smelting Process

Refining the ore to extract the raw metals for use in casting (in this case, bronze) is the prime objective of a mining area. The melting point of pure copper is 1083°C. In order to acquire raw materials of the highest purity, a mining area must have many high-temperature smelting furnaces.

Diagram of a reconstructed furnace

The Workshop for Casting Bronze

The Advanced Art of Bronze Casting

The bronze casting techniques developed in ancient China reached heights that rival or even surpass those of modern methods. First came the piece-mold process, followed by the lost-wax method. The creation of the mold was one of the most important stages in the casting process, because the craftsman could determine the size and shape of the final piece. In other words, it became the "model" for the end product. The evolution of the piece-mold method began with the casting of the whole piece followed later by separate casting and the combination of individual pieces. The lost-wax method allowed for the creation of exquisite openwork in the details of bronze pieces.

Simulation of the bronze casting process

Trends in Revivalism -- The Art of Archaism

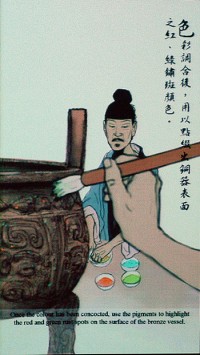

Having endured the ravages of time and hazards of the elements, the surfaces of bronze vessels that you see today have undergone extended periods of chemical reactions that often generated a form of corrosion known as patina. Stable forms of corrosion are actually beneficial and can serve as a protective membrane for the object, but malignant forms (known as "bronze disease") require immediate professional conservation treatment.

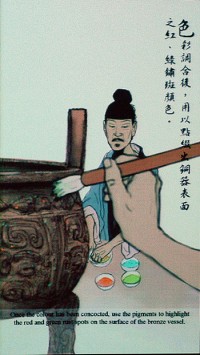

The act of revivalism is a way of going back in history, and it is also an opportunity to gain a better understanding of and rapport with advanced elements of the distant past. Ancient artifacts that have been excavated and rediscovered have attracted much attention from scholars ever since the Sung dynasty (960-1279). The investigation of ancient works of art grew increasingly prevalent, becoming so popular that it reached a peak during the Ming (1368-1644) and Ch'ing (1644-1911) periods. Those who were fond of antiquity went to no expense to recreate a living environment of "archaic elegance". As a result, be it a scholar searching for a refined and classical lifestyle, or an aristocrat or merchant trying to take on the airs of lofty archaism, all had a special passion for objects and vessels that simulated and suggested the forms and styles of the ancient past. With the demands created by such a market, great numbers of archaistic works of art were produced everywhere. As to how bronze vessels were imitated in the Ming and Ch'ng dynasties, the answer lies in the animation of this exhibition!

Producing imitation corrosion

Text and images are provided by National Palace Museum

|