|

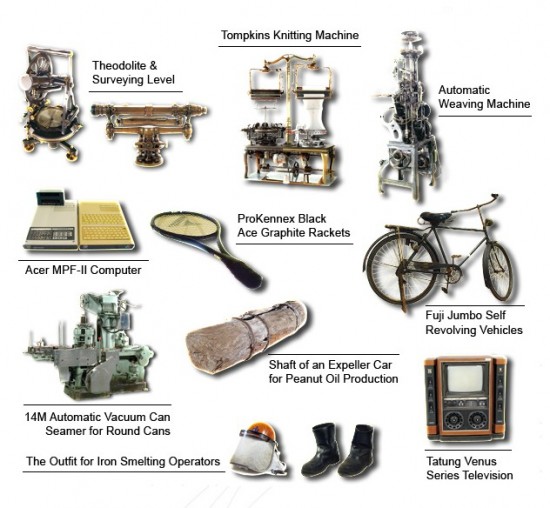

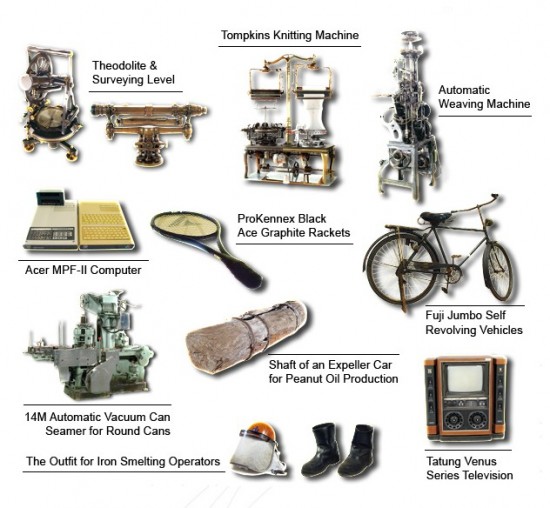

Throughout Taiwan’s economic development, many of Taiwan’s industries swept international markets, established numerous “Taiwan No. 1” records and earned huge amounts of foreign exchange. Based on Taiwan’s unique industrialization process, critical role in the global commodity chain and technical advantages, the tennis racket, footwear, textile, bicycle and personal computer manufacturing industries have been chosen to showcase the unique entrepreneurial and fighting spirits of the Taiwanese.

1. Tennis Racket Manufacturing Industry

Taiwan’s badminton racket producers began making tennis rackets when tennis became popular and foreign companies flocked to Taiwan due to her manufacturing capacity.

Taiwan’s badminton racket producers began making tennis rackets when tennis became popular and foreign companies flocked to Taiwan due to her manufacturing capacity.

After the cold war, cutting edge technology was increasingly used in civilian products; tennis rackets entered the ultra light and high performance era with the introduction of graphite rackets.

In 1977, the founder of Guang Nan Co., Guangnan Luo, saw the light and strong “graphite racket” prototype in US. This chance encounter started a revolution in tennis racket materials and was the beginning of Taiwan’s tennis racket legend.

Guang Nan Co.’s first graphite tennis racket not only replaced wooden rackets, but also changed the worldwide tennis racket industry. Taiwan became the “Tennis Racket Manufacturing Powerhouse”

|

|

ProKennex Black Ace Graphite Rackets

|

2. Shoe Making Industry

Taiwan began using plastics in footwear from the 1960s. In the past, plastics were mainly used for making the soles of slippers and sandals. From 1963, the number of plastic footwear manufacturers multiplied to supply the flood of orders from overseas. Taiwan began using plastics in footwear from the 1960s. In the past, plastics were mainly used for making the soles of slippers and sandals. From 1963, the number of plastic footwear manufacturers multiplied to supply the flood of orders from overseas.

Most people consider natural leather to be superior. However, unlike synthetic leather, natural leather is prone to scratching and molding. During 1970s, Taiwan produced 50% of the world’s PU synthetic leather and produced as much as 200 million square yards of it in 1994. After 1998, due to competition from Mainland China, Taiwan’s manufacturers began searching for new footwear materials.

In 1993, San Fang Chemical Industry achieved a breakthrough and produced a 0.001 denier super-fine fiber. 2000 strands of this fiber is equivalent to one strand of your hair! San Fang Chemical Industry easily clinched orders from world famous brands such as Nike and Timberland.

From making straw shoes to producing for the world, Taiwan’s footwear industry already occupies a crucial role in the global division of labor.

Successful examples include: San Fang Chemical Industry, Hung Cheng Industry, King Steel, GRECO, ASO, Miss Sofi and Feng Tay Co. The government is also heavily involved in leading the industry’s research and development efforts through various organizations such as the Industrial Technology Research Institute.

Today, Taiwan’s footwear industry not only assembles, glues and sews shoes, but is also trying to create a valuable pair of “golden shoes” for Taiwan.

3. Textile Industry

In 1950, with US assistance in cotton, equipment and favorable government policies, Taiwan’s textile industry prospered quickly. In 1950, with US assistance in cotton, equipment and favorable government policies, Taiwan’s textile industry prospered quickly.

By 1957, Taiwan produced a surplus of cotton fabric that could be exported.

Between 1950 and 1960, the government promoted regulations favorable for overseas Chinese to invest in Taiwan. After 1967, ready-made clothes became Taiwan’s major textile export, replacing yarn and gauze. From 1990, synthetic fabrics replaced ready-made clothes and became the chief textile export.

After 1986, the rise in labor costs and environmental awareness caused a wave of overseas relocations in the textile industry. When restrictions on mainland investments were relaxed in 1993, large manufacturers began investing on the mainland in areas such as synthetic fibers where Taiwan had a competitive advantage.

Due to the relocation overseas and the abolishment of quotas in 2005, Taiwan’s manufacturers formed strategic alliances in design, research and development. Many companies even intended to create Asian brands in order to take on the Mainland Chinese market.

|

|

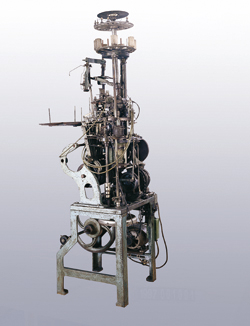

| Tompkins Knitting Machine |

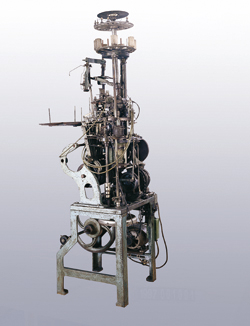

Automatic Weaving Machine |

4. Computer Manufacturing Industry

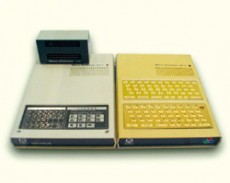

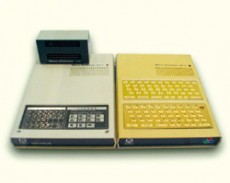

1970s, Taiwan’s calculator industry gave birth to the computer industry. 1970s, Taiwan’s calculator industry gave birth to the computer industry.

1980s, video game engineers accidentally entered Apple II’s microcomputer world.

1990s, Taiwan became the world’s notebook computer manufacturing base.

After 2000, semiconductor, LCD panels let Taiwan shine again on the world stage. After 2000, semiconductor, LCD panels let Taiwan shine again on the world stage.

Based on the distribution of the information industry, the 21st century Taiwan is ranked together with Korea, Singapore and Mainland China as “highly competitive”; Taiwan’s computer industry must face up to the challenges of the future.

Acer MPF-II Computer, 1982

5. Bicycle Manufacturing Industry

Energy crisis during 1960s and 1970s caused many countries to promote the use of bicycles and public transport. Overseas orders for bicycles flooded into Taiwan.

Energy crisis during 1960s and 1970s caused many countries to promote the use of bicycles and public transport. Overseas orders for bicycles flooded into Taiwan.

From 1967, Taiwan’s bicycle manufacturers turned to the international market. The banana shaped High Raiser Bicycle was immensely popular in the US and Taiwan’s bicycle export reached a high of 1.313 million bicycles in 1973.

The bicycles of the 1990s challenged different terrains and environments. Mountain bikes and lighter bicycles became the mainstream products.

With the cooperation between Industrial Technology Research Institute and manufacturers, a magnesium alloy frame weighing only 7kg, or a quarter of a traditional steel frame, was created in 1997.

Facing a worldwide increase in cyclists and environmental awareness, bicycles of the future will move towards high quality and multi-purpose. Bicycles will be designed not only for comfort and fashion, but also for price-performance ratio, safety, light-weight…etc. Internal hub gears will become mainstream and electric powered bicycles will also be popular due to environmental protection considerations.

|

|

Fuji Jumbo Self Revolving Vehicles

|

6. Food Industry

After World War II, both materials and foreign exchange earning were insufficient in Taiwan, so it became an important policy to make foreign exchange earning by exporting goods. In 1950s, food industry played such significant role. Food industry in Taiwan tried its best to make foreign exchange earning. In spite of the poor condition for the development in Taiwan, the cheap human forces brought top one production in the world with the barren land. Taiwan produced everything needed by the world. It expressed the trading features of Taiwanese industries.

After World War II, both materials and foreign exchange earning were insufficient in Taiwan, so it became an important policy to make foreign exchange earning by exporting goods. In 1950s, food industry played such significant role. Food industry in Taiwan tried its best to make foreign exchange earning. In spite of the poor condition for the development in Taiwan, the cheap human forces brought top one production in the world with the barren land. Taiwan produced everything needed by the world. It expressed the trading features of Taiwanese industries.

The development of Taiwanese food industry is traced back to Japanese Ruling Period. The establishment of new sugar factories and canned pineapple factories is the beginning. However, World War II broke the development of Taiwanese food industry.

In 1950s, Taiwanese agriculture has been almost recovered. The “Export Tax Rebate System” of salt and sugar brings the hope to conserves. It also provides opportunities to the exports of processed food and leads to the development of canned pear, mushroom, asparagus, and sea food. Besides, with the effect of land reform, active development of import substitution, and four-year economic construction project, our agriculture is not only self-sufficient but able to develop high-value economic crops. These are the beneficial conditions for the stable development of processed food industry. In the latter half of 1960s, every country’s post-war life style changed and frozen food became the new mainstream of exports.

In 1970s, Taiwan was economically prosperous and food industry began its fast development. Processed agricultural products were rising. The exports of canned food kept increasing. Canned pineapple, mushroom, and asparagus remained top one in the world.

Due to the cost increase of raw materials and human force, the vantage of price no longer remained. In the end of 1970s, Taiwan turned into import-oriented. Besides, the polychlorinated biphenyls pollution of rice bran oil happened in 1979. Civilians began noticing food sanitation and safety, so Council of Agriculture and Industrial Development Bureau were planning the standardization of sanitation and safety in the production of food.

Since 1980s, the environment of food industry gradually changed. In 1990s, Taiwanese food industry turned into the “specific consumption and high value-added product-oriented” phase. Because of the increase of national income, more and more leisure time, spread of education, promotion of information, and enhancement of health consciousness, civilians’ requirements are not just satisfaction in food but how to eat and drink in a healthier and safer way. At the same time, with the development of biotechnology, various customized foods with high performance are produced.

|

|

|

| |

14M Automatic Vacuum Can Seamer for Round Cans |

Shaft of an Expeller Car for Peanut Oil Production |

7. Household Appliance Industry

Taiwan did not have its own home electronics manufacturers until the end of the Second World War. Most home electronic appliances were imported from Japan and other countries. Taiwan started to have home electronics stores in the 1930s. Many Japanese businesspeople chose to open radio and recorder stores in Sakae, today’s HengYang Road. Some Taiwanese businesspeople imported components from Japan and assembled radio for sale. These radios could be found in Dadaocheng. Taiwan did not have its own home electronics manufacturers until the end of the Second World War. Most home electronic appliances were imported from Japan and other countries. Taiwan started to have home electronics stores in the 1930s. Many Japanese businesspeople chose to open radio and recorder stores in Sakae, today’s HengYang Road. Some Taiwanese businesspeople imported components from Japan and assembled radio for sale. These radios could be found in Dadaocheng.

Taiwan’s home electronics industry was not developed until 1948. It was the year when Taiwan saw the first local radio manufacturing shop. Japan’s colonization over Taiwan ended with the Second World War, and domestic trades between Taiwan and Japan became international. Without trade relations with Japan, Taiwan’s home electronics manufacturers managed to find components and technologies from China. Taiwan’s home electronics businesses used to exchange with and learn from their Chinese counterparts. Such cooperation was ceased when cross-strait relations tensed and Taiwan declared Martial Law.

The government of Taiwan restricted the import of radios out of fear that with radio Taiwanese people may communicate with people in China or listen to Chinese broadcasts. Important components for radio production were controlled by the Garrison Command (Taiwan’s KGB). Unable to import components, Taiwan’s businesses turned their assembly plants into factories that manufacture the components needed. This marks the start of Taiwan’s electronics industry.

Taiwan passed its Statute for the Establishment and Administration of Export Processing Zone, to encourage the industrial pattern of export processing.

To analyze the development of Taiwan’s electronics industry, the influx of American capitals was intended to aid Taiwan but dominated Taiwan’s market in the end because the United States cooperated with state-run enterprises in Taiwan. On the other hand, this directed Taiwanese manufacturers to target at American market only and included the cheap labor in Taiwan in American labor force.

The export-oriented economic policies successfully led to economic growth. With increased income, local customers could afford home electronics appliances too. The protectionism policies also guaranteed a platform for local industries, an important factor for prosperity.

Trade liberalization started in the 1980s. Taiwan and other emerging industrial countries were requested to remove or reduce trade practices including duties, surcharges, and export subsidies. Taiwan agreed to the requests, and lost its price advantage. Foreign investors left Taiwan for China and refused to transfer technologies to Taiwan. Taiwanese businesses could not compete in the global arena and its market share shrank. Only a few companies succeeded in transformation from OEM to ODM because of their superb industrial design.

|

|

| |

Tatung Venus Series Television |

To view Part II.

Text and images are provided by National Science and Technology Museum

|

After 2000, semiconductor, LCD panels let Taiwan shine again on the world stage.

After 2000, semiconductor, LCD panels let Taiwan shine again on the world stage.